Pavement design

In airport construction, ground preparation and pavement work are critical processes for ensuring safety and durability. Here, we will explain the advanced construction methods adopted on Phase 2 island and their benefits.

Roller Compaction Method

The land reclamation on Phase 2 island is carried out using the “roller compaction method.” In this method, compaction is performed in thin layers (approximately 60 cm thick per layer) using a large vibratory roller. The roller compaction method generates vibration force by rotating the weights inside the vibratory roller (vibration axis), effectively compacting the soil through the combined effect of its own weight and the vibration. Under meticulous quality control, this method ensures uniform and strong compaction strength.

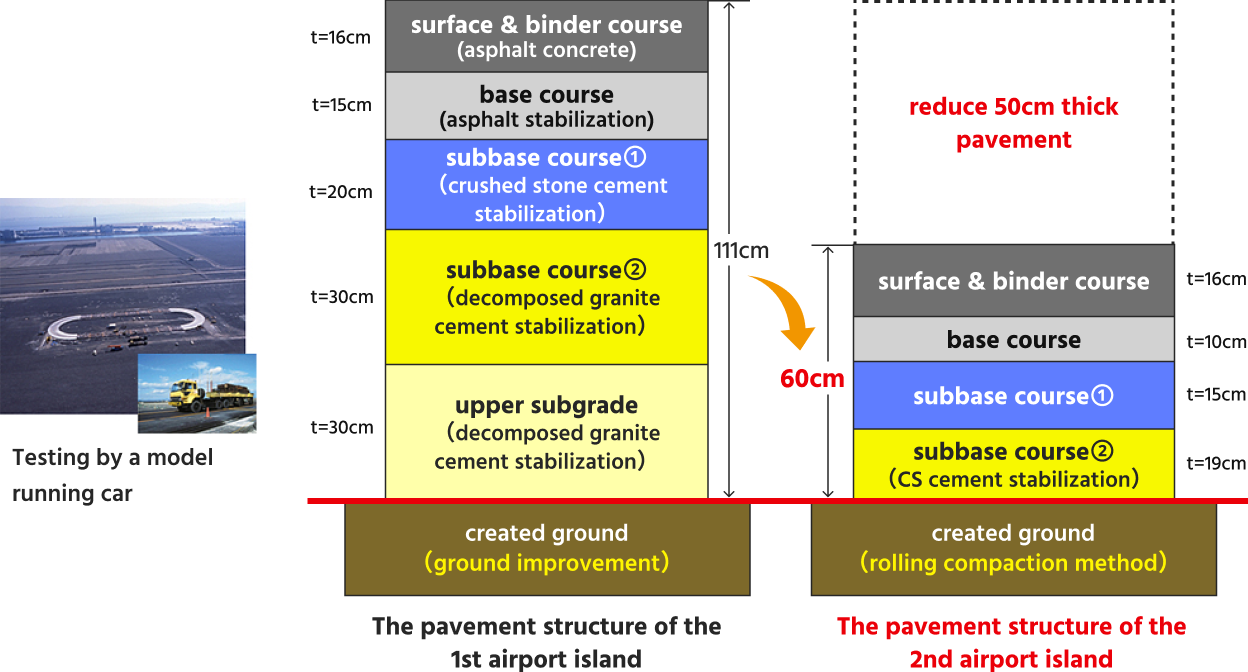

Optimization of Pavement Thickness

In the pavement design for the Phase 2 runways and taxiways, a rational and cost-effective method was adopted, utilizing the characteristics of the underlying ground. First, a circuit-shaped test track was constructed, and over 15,000 test runs were conducted using a vehicle weighing the same as a jumbo jet. The durability of the ground and the stability of the pavement were verified. Consequently, it was confirmed that the ground had sufficient strength, allowing the pavement thickness to be reduced to half of that used in Phase 1. As a result, we successfully achieved a significant reduction in costs.

Development of new pavement design

On Phase 2 island, during the installation of embedded aviation lighting, the lower bases of the lighting units and electrical conduits were pre-installed and secured on the sub-base course before the asphalt pavement was laid. A new construction method, the “embedded aviation lighting pavement-integrated installation method,” was developed, where the upper base course is constructed over the embedded lighting system.

Patent No. 4384148, "Method and Structure for Installing Light Fixtures"

Co-patent application by Obayashi Road Corporation, NIPPO Corporation, and Taisei Rotec Corporation

Features and Benefits of the Construction Method

Compared to traditional methods, this construction method allows for alignment with the pavement installation process, eliminating the need for upper base course milling and asphalt backfilling steps. In addition, since no specialized heavy machinery is required and the work can be carried out by general laborers, this method significantly contributes to reducing both construction time and costs. Furthermore, since it eliminates the discharge of cutting waste, which is classified as industrial waste, this method significantly reduces environmental impact.

Construction Procedures

In the integrated construction method, before asphalt paving, the lower bases and electrical conduits are directly installed and secured onto the completed sub-base course (cement-stabilized layer), followed by asphalt paving over it.

Aviation Lighting System

The aviation lighting system on Phase 2 island incorporates cost-effective domestic and international products for lighting fixtures, including runway lights and taxiway lights.

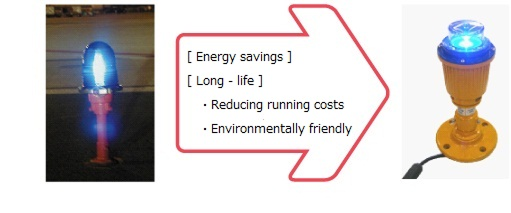

Introduction of LED devices

We adopted LED (light emitting diode) lighting for taxiway lights, the first time in a domestic airport.

The electricity consumption of LED devices is only 1/3 of what halogen ones consume, and their lifespan is 50-100 times longer, ultimately beneficial for the global environment.

Development of original upper base of aeronautical lights

We developed the upper base of aeronautical lights, making the design small and simple. By downsizing our work, the efficiency improved and its production became easier by reducing its cost.

Patent No. 4399609, "Sign Light Mounting Device"

Co-patent application by Tokunaga Manufacturing Co., Ltd.